Computational Materials Design – From Materials Genome to the Development of New Materials and Their Applications

Author(s)

Ren-Chain WangBiography

Dr. Ren-Chain Wang currently serves as a Vice President of ITRI and the General Director of Green Energy and Environment Laboratories. He got his Ph.D. degree in Chemistry from the University of Illinois at Urbana-Champaign. Dr. Wang also co-founded the Chitec Chemical Company and worked for the Shell Development Company.

Academy/University/Organization

Industrial Technology Research Institute-

TAGS

-

Share this article

You are free to share this article under the Attribution 4.0 International license

- ENGINEERING & TECHNOLOGIES

- Text & Image

- November 16,2021

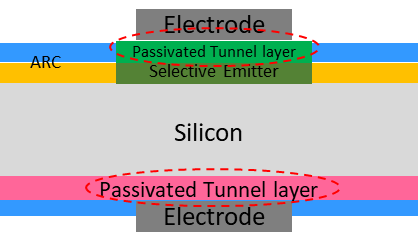

The current barrier to improving the efficiency of traditional silicon crystalline solar cells and the popular Passivated Emitter and Rear Cell (PERC) silicon crystalline cells lies in the carrier recombination effect on the interface between the silicon wafer and the metal electrode. The Tunnel Oxide Passivated Contact (TOPCon) technology developed by the Industrial Technology Research Institute (ITRI) addresses this carrier recombination effect by employing ultra-thin (1~1.5nm) silicon oxide and poly-silicon stacks to form a carrier selective contact structure. TOPCon offers three advantages: improving efficiency, higher return on investment, and shorter payback periods. Specifically, the TOPCon cell efficiency reaches 23.5%, whereas the highest average efficiency from the commercial products is 22.6%. With higher efficiency, the TOPCon cell reduces the required surface area by more than 4%; improves power generation capacity during rainy days, and decreases the power attenuation by 3% at high temperature, which is very suitable for Taiwan's weather conditions. With a return on investment (ROI) of less than two years, the TOPCon technology can upgrade Taiwan’s current mainstream solar PERC production lines, with the expectation that TOPCon technology can elevate Taiwan’s Photovoltaic (PV) industry and secure its global leadership position.

To address the challenges of climate change and environmental impact, more than 130 countries have announced their net zero emissions target, with over 24 countries having established or introduced legislation to achieve the net zero goal by 2050. Increasing the power generation proportion from renewable energy sources has been the key topic for the carbon reduction research and development as well as current policy priority. Solar energy has been one of the critical players among renewable energy sources. With the government’s effort, Taiwan's solar power generation capacity increased from 1,109 GWh (million kWh) in 2016 to 6,095 GWh in 2020. However, Taiwan’s PV development is impacted by several geographical and environmental conditions, which include limited land area with a dense population, and the damp and humid weather conditions which also reduce the average solar radiation intensity. As such, the development of solar cells with higher efficiency has greater importance to power generation.

Currently, 90% of the solar cell market is crystalline silicon solar cell products with the majority being the p-type cell, and the average efficiency is about 18%. The PERC solar cell—which was derived from the p-type silicon solar cells—has more than 65% of the market share currently, with the highest conversion efficiency of about 22.6%.

The way solar cells generate power is by absorbing solar radiation in the absorption layer, which produces free electron-hole pairs. The current must be collected in external electrodes by the internal electric field before the electrons and holes are recombined. When the energy state density on the metal electrodes and silicon interfaces is high, it will accelerate the recombination rate of electrons and holes on the interface. This recombination effect of the interface between the crystalline silicon and metal electrode is the main reason why the conversion efficiency of traditional crystalline silicon cells and PERC cells has reached a bottleneck.

The Tunnel Oxide Passivated Contact (TOPCon) technology developed by ITRI can be regarded as the next generation of the PERC structure technology (Figure 1). The key to TOPCon technology is the integration of ultra-thin (1~1.5nm) tunneling silicon oxide and poly-silicon film stack as passivated contact to form a carrier-selective contact structure. The TOPCon design decreases the recombination effect and improves the conversion efficiency of the solar cells thanks to the tunneling effect and field effect.

Figure 1. TOPCon PV Structure Design

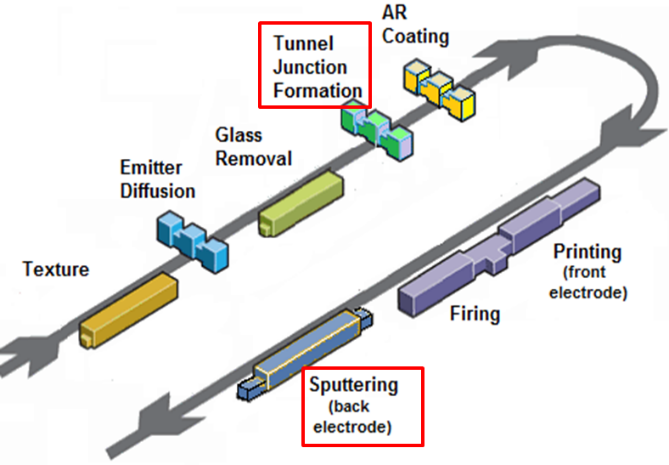

The TOPCon technology offers three advantages: it improves energy conversion efficiency, gives higher return on investment, and has a shorter payback time. The TOPCon cell efficiency reaches 23.5%, whereas the highest efficiency from the commercial PERC products is around 21.6~22.6%. Aside from newly installed solar cells, replacing outdated solar cells with high-efficiency TOPCon cells can save more than 4% of the land area. It can also enhance the power generation capacity during rainy days, and reduce the power attenuation by 3% at high temperatures, which is very suitable for Taiwan's climate. The TOPCon technology can be integrated directly into the existing mainstream PERC production lines. The integration of TOPCon technology only requires adding the Low Pressure Chemical Vapor Deposition (LPCVD) and sputtering process, without the need to revamp the entire production line. As such, the ROI for TOPCon technology is less than two years (Figure 2).

Regarding TOPCon technology, ITRI has been collaborating with Motech Industries Incorporation to establish a demonstration production line for TOPCon cells (Figure 3), and to connect the upstream, midstream and downstream firms to form a high-efficiency PV national team. It is expected that the TOPCon technology will elevate Taiwan’s PV industry and secure its global leadership position.

Figure 2. Upgrading PERC production line to TOPCon

Figure 3. TOPCon Demonstration production line in Motech Industries Incorporation

STAY CONNECTED. SUBSCRIBE TO OUR NEWSLETTER.

Add your information below to receive daily updates.