Advanced Quality/Process/Equipment Control for Semiconductor Smart Manufacturing

Author(s)

Kung-Yen LeeBiography

Kung-Yen Lee received his Ph.D. degree in electrical and computer engineering from Purdue University in the USA. He is currently a Professor with the Department of Engineering Science and Ocean Engineering and deputy director of the NTU-ITRI Nano Center in National Taiwan University. His research interests include SiC material characterization and SiC power semiconductor devices. He received the future tech award in 2019, the first prize of the FITI (From IP to IPO) program in 2020 and the TRUSTU (Taiwan Reputed University Startups to Taiwan Unicorns) program in 2021.

Academy/University/Organization

National Taiwan University-

TAGS

-

Share this article

You are free to share this article under the Attribution 4.0 International license

- ENGINEERING & TECHNOLOGIES

- Text & Image

- April 14,2021

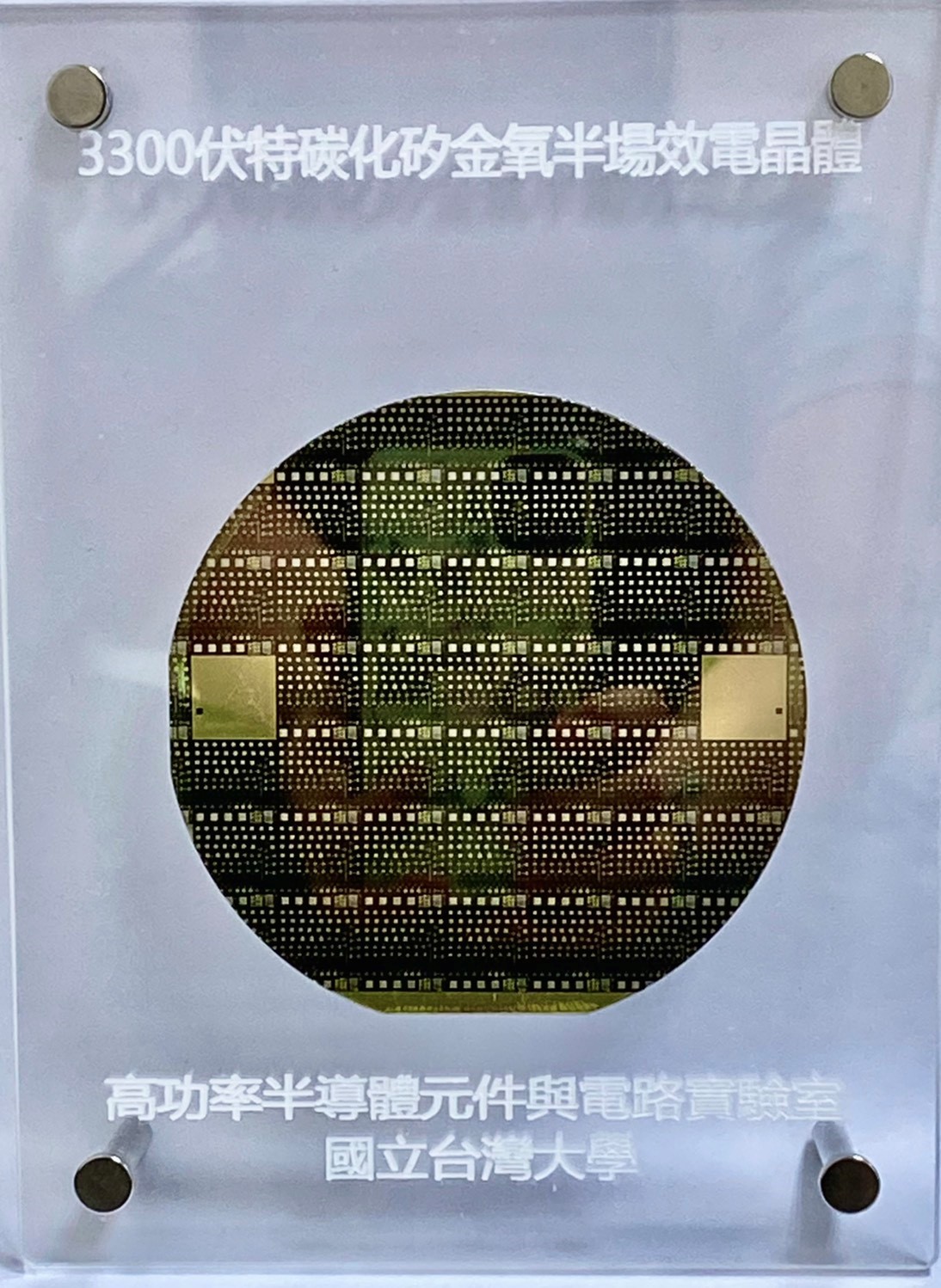

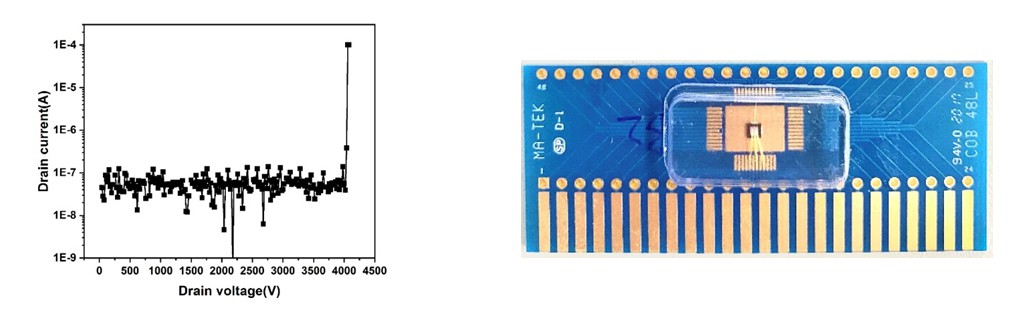

The research group of Prof. Lee has overcome the disadvantages of SiC semiconductor material and the limitations of the 4-inch semiconductor manufacturing equipment and has successfully developed 1200 V SiC super junction MOSFETs which can increase energy conversion efficiency and reduce power loss. Subsequently, through numbers of calculations and simulations, the reverse breakdown voltage of 4H-SiC MOSFET is increased, and the specific-on resistance and reverse leakage current are reduced. The research group of Prof. Lee then developed 3300 V 4H-SiC MOSFETs which have a breakdown voltage of over 4000 V and a very low reverse leakage current under higher reverse bias.

The SiC power semiconductor devices developed by the research group of Prof. Lee can be applied in 5G systems, renewable power systems, electric vehicles and defense industries, not only saving energy and reducing carbon emissions, but also developing the third generation semiconductor and defense industries in Taiwan. Therefore, SiC semiconductors are the key technology of the development of Taiwan in the near future.

In order to save energy and reduce carbon emissions, the efficiencies of renewable power systems, electric vehicles and rail systems must be increased and the power dissipation must be reduced. In these systems, the power semiconductor devices (diodes and MOSFETs) play important roles. During the turn-on and turn-off periods of the converters / inverters, the switching power loss and conduction power loss are generated inside these power semiconductor devices. Therefore, during the conduction period, the power semiconductor devices must have lower specific-on resistance to reduce power loss; during the switching period, the power semiconductor devices must have a low leakage current. In addition, the reverse recovery time must be short so that the device can be turned off quickly.

In the concept of semiconductor materials, the electric field of SiC material is 10 times higher than that of Si material so that SiC semiconductor devices can reduce the specific-on resistance; SiC semiconductor devices can be operated at higher temperatures without causing a high leakage current due to the properties of low intrinsic concentration and wide band gap; the switching loss of SiC semiconductor devices is very small due to the short reverse recovery time. Therefore, SiC semiconductor devices can be operated at higher frequency with the smaller and lighter power system and heat sink. If the SiC diode is applied in the PFC, the volume and weight of the PFC is 38% smaller and 44% lighter. Power loss is reduced by 60% and 36% if the SiC devices are applied in air conditioners and trains respectively. SiC devices were installed in the Japanese high speed rail N700S in 2020, reducing power loss by 7%. SiC devices were also applied in the Tesla Model 3 electric car to increase its range and reduce its weight.

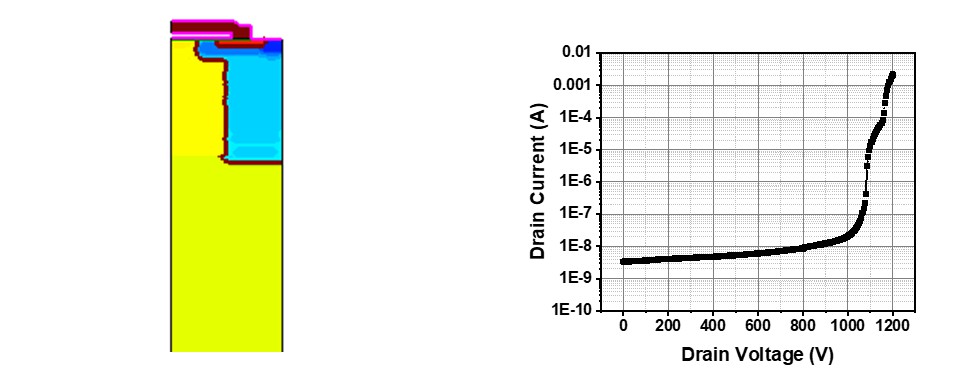

The research group of Prof. Lee focuses on the SiC power semiconductor, including SiC epilayer growth, analysis of the epilayer, design and simulation of SiC power semiconductor devices, layout, fabrication processes and characterization. Recently, Prof. Lee developed the 1200 V SiC super junction MOSFET and 3300 V SiC MOSFET. The super junction structure is to create P-type pillars inside the conventional MOSFET structure by P-type ion implantation, as shown in Fig. 1. The P-type pillars make the electric field inside the MOSFET uniform and deeper so that the reverse breakdown voltage can be increased. In other words, under the same reverse breakdown voltage, the specific-on resistance can be significantly reduced. The specific-on resistance of the super junction MOSFET is proportional to the power order of 1.3 of the breakdown voltage. (The specific-on resistance of the conventional power MOSFET is proportional to the power order of 2.5 of the breakdown voltage!) Therefore, SiC power semiconductor devices applied in power systems can significantly reduce power dissipation.

The research group of Prof. Lee has overcome the disadvantages of SiC semiconductor material and the limitations of the 4-inch semiconductor manufacturing equipment, and then successfully developed 1200 V SiC super junction MOSFETs using the multiple epilayer growth and ion implantation technologies. The breakdown voltage is about 1200 V with low reverse leakage current as shown in Fig. 2, which can increase the energy conversion efficiency and reduce the power loss. Subsequently, through numbers of sophisticated calculations and simulations, the reverse breakdown voltage of 4H-SiC MOSFET is increased, and the specific-on resistance and reverse leakage current are reduced. Therefore, the research group of Prof. Lee also developed 3300 V SiC MOSFETs which have the breakdown voltage over 4000 V and very low reverse leakage current under higher reverse bias as shown in Fig. 3. Fig. 4 shows a single 1200 V SiC super junction MOSFET which is bonded on the circuit board for demonstration.

According to Yole Development, the global market of SiC semiconductor devices will be more than 60 billion Taiwan dollars in 2023 and the Compound Annual Growth Rate (CAGR) will reach 31%. The SiC power semiconductor devices developed by the research group of Prof. Lee can be applied in 5G systems, renewable power systems, electric vehicles and defense industries, not only saving energy and reducing carbon emissions, but also developing the third generation semiconductor and defense industries in Taiwan. Therefore, SiC semiconductors are expected to be the key technology of the development of Taiwan in the near future.

Fig. 1 A simulated structure of a SiC super junction MOSFET ; Fig. 2 Reverse breakdown voltage of a SiC super junction MOSFET

Fig. 3 the reverse breakdown voltage of a 3300 V SiC super junction MOSFET over 4000 V ; Fig. 4 A single 1200 V SiC super junction MOSFET is bonded on the circuit board.

STAY CONNECTED. SUBSCRIBE TO OUR NEWSLETTER.

Add your information below to receive daily updates.