Privacy Protection and Personal Information De-Identification for Artificial Intelligence Applications

Author(s)

Yi-Hung Chen & Min-Hao YuanBiography

Dr. Yi-Hung Chen is Distinguish Professor of the Department of Chemical Engineering and Biotechnology, National Taipei University of Technology. He obtained his Ph.D. in Environmental Engineering, National Taiwan University in 2003 and served as a researcher at the Karlsruhe Institute of Technology (Germany) and at the University of California, Berkeley (US). His research interests focus on bio-based oil, ester processing technologies and high-gravity rotating packed bed technologies for environmental pollution controls. He has executed the MOST Industrial Value Creation Project to build a startup company, and received several excellent research awards from the Taiwan Institute of Chemical Engineers and Chinese Institute of Environmental Engineers, such as Young Investigator’s Achievement Award (2011) and Excellent Young Engineer Award (2015).

Dr. Min-Hao Yuan is Assistant Professor in the Department of Occupational Safety and Health, China Medical University. He received his Ph.D. in Environmental Engineering from National Taiwan University in 2011 and conducted research in the University of Tokyo and Tokyo Institute of Technology (Japan) and the University of Michigan-Ann Arbor (US). His research focuses on bio-based oil, ester optimization and air pollution control. He received the Excellent Paper Award from the Taiwan Institute of Chemical Engineers and Chinese Institute of Environmental Engineers in 2015 and 2019, respectively.

Academy/University/Organization

National Taipei University of Technology-

TAGS

-

Share this article

You are free to share this article under the Attribution 4.0 International license

- ENGINEERING & TECHNOLOGIES

- Text & Image

- November 16,2021

The Environmental, Social and Governance (ESG) strategies have been highly encouraged to promote corporate competitiveness towards sustainability. Prof. Chen and his research team started with an ideate theme of the circular economy from palm oil mill to the Apple supply chain. They developed a bio-based metalworking fluid (MWF) for better quality and yield of high-end products, superior product differentiation, and total solution for ESG. The specialized bio-based MWF is particularly suitable for the machining of hard metal and difficult materials. The on-site performance tests showed an increase in the defect-free rate and lifespan of cutting tools, resulting in productivity improvement and cost reduction. Furthermore, the formula consists of mainly bio-based esters without toxic or allergic components, which diminishes workplace exposure and skin allergies. Bio-based oils can be considered as carbon-neutral material. Prof. Chen’s team also developed several approaches to establish a total solution of the waste MWFs and therefore accomplished a pathway to the circular economy from palm-oil mill to Apple and other high-end product industries.

In face of global climate change, net zero emissions and social responsibility, the promotion of sustainable enterprises is not just a plus. It can offer companies a competitive advantage as stronger and faster ESG (Environmental, Social and Governance) practices will attract sustainable investment, and therefore foster a collaborative environment towards a resilient and sustainable society. With this accelerating trend in the international arena, Taiwan’s government, industry and academia have worked closely to accumulate RD capacity and propose innovation technologies and services to let the ESG agenda and advantages thrive.

Prof. Yi-Hung Chen and his research team started with the ideate theme of the circular economy from palm oil mill to the Apple supply chain. They developed a bio-based metalworking fluid (MWF), which is particularly specialized for the machining of hard metal and difficult-to-cut work pieces. The bio-based MWF would result in better quality and yield of high-end products, superior product differentiation, and total solutions for ESG practices towards a circular economy pathway.

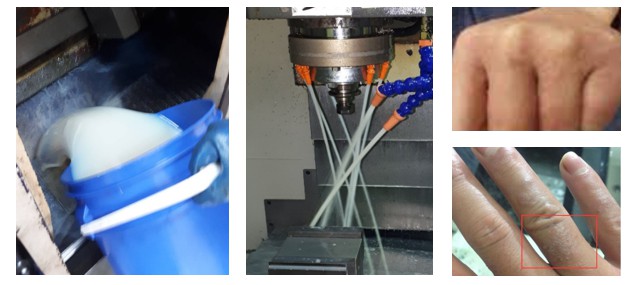

Figure 1. The bio-based metalworking fluid for high-end product manufacturing developed by the research team of Prof. Yi-Hung Chen from National Taipei University of Technology.

CNC (Computer numerical control) machining is becoming a popular manufacturing method primarily in the metal fabrication for customized and special metal-material products because of its accuracy, consistency and efficiency. Although CNC machining is possible for highly detailed cuts out of metal pieces, CNC machines regularly utilize other tools and components for better metalworking performance, such as cutting tools and linear motion control systems. Furthermore, the innovation of metalworking fluid has been recognized as a liquid tool to achieve excellent CNC machining performance for high-end products.

From the support of MOST Industrial Value Creation Project, Prof. Chen and his RD team develop a bio-based MWF product with significant cooling and lubricity to metal components and build a startup company. The base oil utilizes bio-based esters, which have naturally high polarity or affinity for metal surfaces and for forming a tribofilm with desirable lubrication. Furthermore, the bio-based esters are easily emulsified and dispersed in water. The on-site performance tests showed the increase in the defect-free rate and lifespan of cutting tools, resulting in productivity improvement and cost reduction. The installation of bio-based MWF brings new opportunities for the advancement of high-end product fabrication from the Apple supply chain or other difficult-to-cut work pieces (Almelec, Titanium or nickel-based alloys, stainless steel, etc.).

On the other hand, the formula of bio-based MWFs consists of mainly bio-based esters without toxic and allergic components, which diminishes workplace exposure and skin allergies. This inherently safer formula would be valuable to ESG practice in terms of occupational safety and health promotion, as well as mitigating worker shortage in manufacturing. The handling cost for reuse of waste fluid would also be reduced (Figure 2).

Bio-based oils can be considered as carbon-neutral material, and the higher portion of content leads to higher biodegradability. In comparison to conventional mineral oil-based MWF, the bio-based MWFs with toxic-free component would be suitable for more disposal options. Prof. Chen’s team also developed several approaches to establish a total solution for waste bio-based MWFs, such as vacuum distillation by high-gravity rotating packed bed, fractional distillation of bio-based esters, and anaerobic digestion. The team will accomplish a pathway to the circular economy from palm-oil mill to Apple and other high-end product industries.

Figure 2. The bio-based MWF products from HiGee Tech provide significant cooling and lubricity and diminish workplace exposure and skin allergies.

STAY CONNECTED. SUBSCRIBE TO OUR NEWSLETTER.

Add your information below to receive daily updates.