ViSSA 2.0: Virtually Shared Spectrum Access (ViSSA) Experiment and Demonstration Platform 2.0

Author(s)

Shuo-Peng LiangBiography

Dr. Shuo Peng Liang is an R&D manager in the Industrial Technology Research Institute. He is now focusing on the development of 5G industrial use cases such as immersive interaction and cyber-physical control.

Academy/University/Organization

Industrial Technology Research Institute-

TAGS

-

Share this article

You are free to share this article under the Attribution 4.0 International license

- ENGINEERING & TECHNOLOGIES

- Text & Image

- August 17,2021

The term “intelligent manufacturing” has been transformed from a buzz word into a key technology for the survival of industry within a decade. However most domestic manufacturing companies are SMEs which lack the resources to conduct R&D activities or to build test sites for intelligent manufacturing. Therefore, an open demo site would be an important infrastructure to promote intelligent manufacturing as well as a testbed for advanced research projects on 5G, AI and digital twins. In this article, the background of the construction of the intelligent manufacturing technology verification site as well as its technologies and achievements on promotion will be introduced from the perspective of intelligent manufacturing. Linkage with international research partners will also be described.

The Global Trend

The term “intelligent manufacturing” has been transformed from a buzz word into a key technology for the survival of industry within a decade. It is under this global trend that Taiwan’s government issued the intelligent machinery promotion policy, and hence the intelligent manufacturing technology verification site.

On the other hand, the emerging 5G technology will increase the performance of IoT by two orders of magnitude, which will trigger dramatic change in technologies behind intelligent manufacturing such as digital twins and AI. These are the new frontiers that are worth exploring.

Technology and International Linkage

The characteristics that differentiate the intelligent manufacturing verification site from other demo sites is that the machines as well as the target parts are not limited, ranging from industrial sectors such as bicycle, aerospace, automobile, medical, semiconductor and green energy. All machines are built by domestic machine tool companies. IoT, process diagnostics and optimization, and production management software are built in-house and are capable of conducting flexible, massive customization production.

On the other hand, international partners such as Dassault Systems, Siemens, Mitsubishi, Rockwell, Amazon, and Microsoft have been invited to set up demo booths and initiate development projects on IoT, AI, and cloud computing.

Building the Private 5G Industrial Use Cases

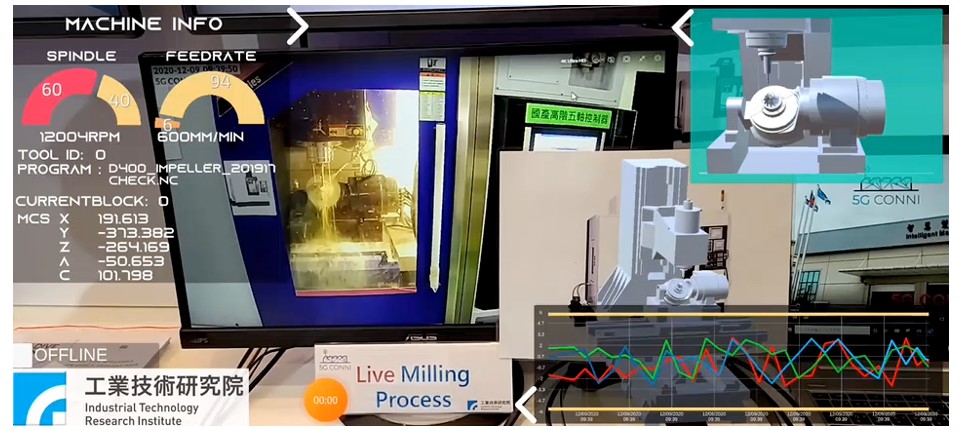

With the progress of standardization and commercialization of the 5G network, we have successfully applied the EU project (5GConni, 5G for connected industry) to explore industrial use cases such as data collection, immersive interaction and remote expert instruction, cyber-physical control, asset tracking with Fraunhofer, Bosch, Cea Leti, Sapienza University of Rome, and Athonet (Figure 1). With the development of the software and hardware testbed, functional and non-functional specifications can be defined for the future development of intelligent factories.

Figure 1. The 5GConni project members

Take the immersive interaction as an example; with the high band width and low latency characteristics of the 5G network, digital twins, machine operators and remote experts can be linked under a virtual factory to resolve problems on product design, process design and diagnostics (Figure 2).

Figure 2. The immersive interaction app

Industrial Benefits

In recent years the intelligent manufacturing technology verification site acted like a planning center for intelligent manufacturing and helped industry to conduct various process optimization, shop floor construction cases. There have been 502 visiting events hosted so far with a total of 1,307 domestic companies, 61 international companies and more than 9,000 visitors, while 18 system integrators have adopted the technologies from the site and helped 81 companies to commit to intelligent manufacturing with a total investment of NT2.8 billion.

Conclusion

During the construction of the intelligent manufacturing technology verification site, the ITRI team transformed from machine user to shop floor manager and eventually to system integrator for shop floor construction and supply chain management. Many industrial partners have started to invest in intelligent manufacturing due to the demonstration of the site. Therefore we believe that the verification site will continue to act as the key infrastructure for intelligent manufacturing and provide the latest solution for the industry.

STAY CONNECTED. SUBSCRIBE TO OUR NEWSLETTER.

Add your information below to receive daily updates.