Advanced Semiconductor Materials Could Help Beat Moore’s Law

Author(s)

Jien-Wei YehBiography

Professor Jien-Wei Yeh obtained his PhD from the Department of Materials Science and Engineering, National Tsing Hua University in 1986. He was awarded as a distinguished professor in 2017. He is currently the director of the High Entropy Materials Center. He won the Industry-University Cooperation Award of the Ministry of Education in 2000; the Ho-Chin-Tue Award of Metallurgy from the Tung-Ho steel company in 2003; Fellow of Materials Research Society-Taiwan, 2015; Outstanding Research Award of the Ministry of Science and Technology, 2016; The highest honor of Materials Research Society Taiwan: Memorial Award of Chih-Houng Lu in 2017; Science Contribution Awards of the CTCI Foundation in 2019, Exceptional Contribution Award of the First World Congress on High Entropy Alloys in 2019; and the 27th TECO Award from the TECO Foundation. He specializes in traditional alloys and high-entropy alloys, and is currently dedicated to researching high-entropy alloys and applying the new technology to industries.

Academy/University/Organization

National Tsing Hua University-

TAGS

-

Share this article

You are free to share this article under the Attribution 4.0 International license

- ENGINEERING & TECHNOLOGIES

- Text & Image

- December 21,2020

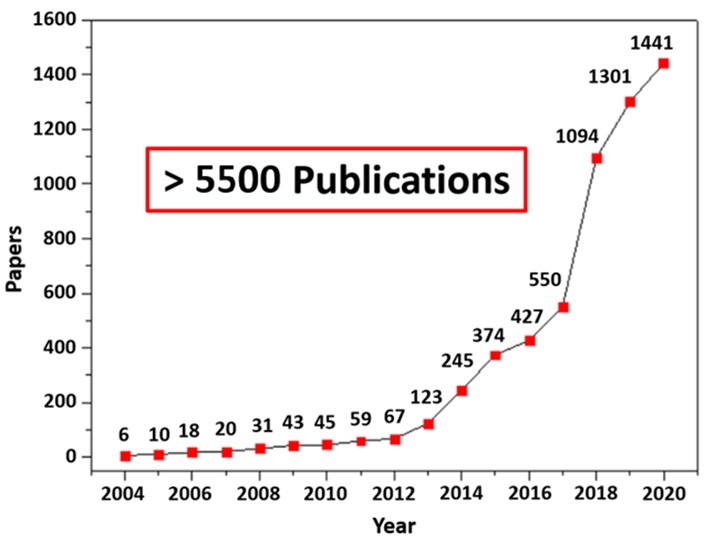

Since ancient times, there has been an unchallenged myth in the manufacture of materials: it is believed that the more kinds of alloying elements that are added in high proportions, the more difficult it is to alloy them together. Even if they could form a bulk material, a large number of brittle compounds will exist in the microstructure and become useless. Professor Jien-Wei Yeh from the Department of Materials Science and Engineering of National Tsing Hua University thought in reverse in 1995. He believed that multiple elements would induce a high entropy effect which promotes their mixing to form solid solutions. Soon after, without papers or books to refer to, he explored and opened up new frontiers. In the 9th year (2004), he published a paper on the concept “High-Entropy Alloys” and another 4 papers on high-entropy alloys. More than 140 papers have been published so far. He named them high-entropy alloys and defined them as having at least five major elements and/or some minor elements, with each major element constituting between 5% and 35%, and each minor element less than 5%. Therefore, he opened up the new field of "high-entropy alloys" in which the global high-entropy papers are growing exponentially. As of October 2020, more than 5,500 papers had been published. Thus, his new composition concept has given new life to the elemental periodic table, resulting in unlimited compositions and properties. At present, he is further introducing high-entropy alloys into the industries of aerospace, advanced machinery, livelihood and others in order to break the bottlenecks, increase efficiency, reduce costs and save resources.

Promising applications of high-entropy materials in different industries

Materials are the mother of industrial technology; high-entropy alloys have created a new era of materials

"High-entropy alloys" are a revolutionary alloy concept which overturned the composition concept that was based on one major element since ancient times, subverting the myth that the more kinds of alloy elements that are added, the more brittle the metals will be. This new materials field originated from Professor Jien-Wei Yeh, Tsing Hua University, Taiwan in 1995. He named and defined “High-entropy alloys” and elucidated the basic principles of high-entropy alloys and their four core effects: high entropy, sluggish diffusion, lattice distortion, and the cocktail effect. High-entropy alloys with a proper alloy design can exhibit special and excellent properties and break through the bottlenecks of traditional materials, including insufficient performance, high cost, or harm to the human body. He has obtained invention patents in Taiwan, China and Japan.

Nature report confirms that high-entropy alloys originated in Taiwan

Professor Jien-Wei Yeh and his team accumulated a large amount of research data and results from 1995 to 2003. In 2004, they published 5 high-entropy alloy papers for the first time. After that, they published an average of 10 high-entropy alloy papers each year. His work has aroused the attention and follow-up of the whole world. Since 2012, high-entropy alloys and related materials papers have shown exponential growth, as shown in Figure 1. In May, 2016, Nature even made a special report on high-entropy alloys: "Metal mixology: stronger, tougher, stretchier." This report confirmed the new field of high-entropy alloys and confirmed the fact that Taiwan is the birthplace.

Establishment of the world's first High-Entropy Materials Center

In 2018, the Ministry of Science and Technology and the Ministry of Education established the world's first High-Entropy Materials center. A total of 30 professors participate in research on different topics, not only pursuing academic excellence but also implementing industrial applications. High-entropy alloys have been proven to have higher hardness, temperature resistance, wear resistance, corrosion resistance, anti-sticky ability and lower cost than commercial traditional alloys. Therefore, they can be used in livelihood, smart machinery, green energy, national defense, aerospace and other industries.

Industrialization of high-entropy materials

In July 2020, the Ministry of Science and Technology subsidized a value-added project to create a high-entropy material technology company to commercialize high-entropy material technology, supplying high-entropy materials to industry, overcoming traditional material bottlenecks, improving competitiveness and expanding the market. The selected high-entropy products are as follows (see Fig. 2):

- The slider of extreme high-entropy alloy for linear slides can replace the traditional slider material.

- Extremely high-entropy alloy oil-well bearings can replace the traditional cobalt-based alloy, and is widely used in oil well drilling, chemical, geothermal and related industries.

- Extrusion dies made of extremely high entropy alloys can be used for hot extrusion of high melting point alloys above 1500ºC.

- Tools made of high-entropy non-sparking alloys are cost-effective and non-toxic. They can replace the current use of high-toxic and expensive beryllium bronze explosion-proof tools for explosive and flammable workplaces.

- The high-entropy antibacterial alloy can be applied to knives, antibacterial railings and antibacterial door handles in the post-epidemic era.

Fig. 1: Growth curve of the yearly number of global high-entropy papers till the end of Sept. 2020.

Fig. 2: Applications of high-entropy alloy products: upper left is a worm gear for CNC machines; lower left is an antibacterial knife; upper right is an oil well bearing; and lower right is a set of beryllium-free and spark-free tools.

STAY CONNECTED. SUBSCRIBE TO OUR NEWSLETTER.

Add your information below to receive daily updates.