Create a Secure Society with Robust Information Security Capability

Author(s)

Shin-Ku LeeBiography

Shin-Ku Lee is a research fellow at the Research Center for Energy Technology and Strategy at National Cheng Kung University. Dr. Lee's current research is concerned with the development of advanced materials for the energy field. He also has a continuing interest in the development of academic-industrial platforms in the green building field.

Academy/University/Organization

National Cheng Kung University-

TAGS

-

Share this article

You are free to share this article under the Attribution 4.0 International license

- ENGINEERING & TECHNOLOGIES

- Text & Image

- November 16,2021

Aerogel with nano-pores, which provides extremely low thermal conductivity and has a low dielectric constant, has caught the attention of industry. However, it cannot be widely used because of its high price, cumbersome manufacturing process, and insufficient mechanical strength.

The research team of the Research Center for Energy Technology and Strategy, NCKU has successfully improved the preparation of aerogel powder with lower cost material, and has simplified the process to make it easier to use. In order to broaden the applications of aerogel, the practical aerogel phenolic foam board with fire and heat resistance, which is lightweight and has low water absorption performance, was developed based on our core aerogel manufacturing technology. We also found that aerogel has great potential to be used in 5G electronic devices. We continue to engage in finding a solution to the aerogel powder aggregation problem, with a 5 μm aerogel powder having been successfully manufactured. By reducing the particle size of the powder, it can still maintain the nano-pore structure for subsequent applications. In 2020, our startup company, that was approved by the Ministry of Science and Technology, was established with the aim of converting this innovative development into commercial applications.

To slow down the speed of global warming, energy saving and decarbonization are very important steps to achieve this mission. Statistics show that the building sector consumes a good 30% of the total energy used in Taiwan. How to reduce building energy consumption and the urban heat island effect has become a focus of immediate attention worldwide. In order to achieve this goal, the development of highly energy-efficient material has always been regarded as the most effective strategy.

Aerogel with nano-pores, which provides extremely low thermal conductivity and has a low dielectric constant, has caught the attention of industry to deliver energy saving and high efficiency at the same time. However, aerogel is still considered as having a high unit price, involves a cumbersome manufacturing process, and has insufficient mechanical strength, not to mention that it requires complicated skill sets to synchronize the composite materials. For these reasons, aerogel cannot be widely used.

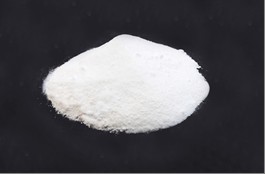

Since 2014, the Research Center for Energy Technology and Strategy, National Cheng Kung University, has made efforts to improve the aerogel manufacturing process to achieve its high cost-effectiveness ratio. The research team developed powdered silica aerogel that is hydrophobic and nano-porous, together with key features such as a high specific surface area, low thermal conductivity, and low dielectric constant. We can control the average particle size at 20μm, that can be mixed with various resins and fiber materials to become functional composite materials (Figure 1).

Figure 1. Aerogel Powder with nano-pores, extremely low thermal conductivity, a low dielectric constant and fire resistance

In order to broaden the applications of aerogel, we added aerogel powder to phenolic resin with a dispersant to form a porous board (Figure 2). These boards offer fire and heat resistance, are lightweight, and have low water absorption performance. This innovative technology can help the construction industry to supply better quality, functional and earth friendly materials in various applications. This proposed foam board complies with fire-resistant material and high-performance energy-saving green building materials standards. It won the innovation award at the 3rd WSSET in 2018 and has been granted patents by the Republic of China, Germany, and Japan.

Figure 2. Aerogel Phenolic Foam Board with fire and heat resistance, lightweight, and low water absorption performance (Specification: 240cm * 120cm * 5cm, density:100~150 kg/m3, non-flammable class 1)

Because the porosity of aerogel is greater than 90%, and because its theoretical dielectric constant is close to that of the air, it has great potential to be used in 5G electronic devices. We have continued to engage in finding a solution to the aerogel powder aggregation problem, and a 5 μm aerogel powder was successfully manufactured. By reducing the particle size of the powder, it is still possible to maintain the nano-pore structure for subsequent applications. There are additional features such as the dielectric constant near air Dk~1, the thermal stability of materials over 300°C, halogen-free, and contact angle of over 150 degrees, which are all suitable for materials used in the semiconductor industry.

In 2020, our startup company, approved by the Ministry of Science and Technology, was established with the aim of starting to convert this innovative development into commercial applications.

STAY CONNECTED. SUBSCRIBE TO OUR NEWSLETTER.

Add your information below to receive daily updates.