Supply Chain Security Threats Hunting

Author(s)

Tzong-Ming LeeBiography

Tzong-Ming Lee, General Director of the MCL/ITRI, is a PhD in chemical engineering from National Tsing Hua University, specializing in photoelectric organic polymer materials and nanocomposites. As leader of the most important materials and chemical research and development institute in Taiwan, Dr. Lee leads the R&D team to cooperate with domestic industry, academia, and associations in order to develop innovative materials for application in various fields including optoelectronics, semiconductor packaging, PCB, chemical and biomaterials, textiles and commercial chemical industries.

Dr. Lee helped the technology upgrade of the materials industry and increased product values. Through the increased cooperation and linkage with well-known international manufacturers and academic research institutes in Europe, the USA and Japan, Taiwan's innovative materials technology can reach international markets. He also served as the deputy director of the "Net Zero Sustainability Strategy Office," and was actively involved in the development of key materials technology for the circular economy and the industry's net zero sustainable transformation.Academy/University/Organization

National Tsing Hua University-

TAGS

-

Share this article

You are free to share this article under the Attribution 4.0 International license

- ENGINEERING & TECHNOLOGIES

- Text & Image

- November 16,2021

Global climate action and carbon neutrality have become the key issues to international consensus for sustainable development. Taiwan is export-oriented and a key player in the global supply chain, where it is having a profound impact. Facing the declaration of the 2050 net zero emission in various countries, the world has focused on two major carbon reduction practices, namely "renewable energy development" and the "circular economy" based on the consideration of energy structure and manufacturing processes. The Material and Chemical Research Lab. of the Industrial Technology Research Institute (MCL/ITRI) has long been concerned about international technology trends and material technology research and development. It also regards the circular economy as an important means of net-zero sustainable development, and has tried to introduce new circular economy methods into industrial production, from original material design to a manufacturing process incorporating concepts such as redesign, recycling and deploying a number of recycled materials and process technologies in the panel industry, bio-plastics, solar photovoltaic and other industries. It is expected that these efforts will help to unlock the net-zero transformation of Taiwan’s industry and move towards net-zero emissions simultaneously with the rest of the world.

With the pursuit of economic growth in the past, the environmental issues have long been ignored. With the frequent occurrence of climate disasters around the world in recent years, scientists have confirmed that the high carbon emissions generated by human activities have indeed led to extremes in the climate, and that the damage to the environment is irreversible. Therefore, advanced countries have taken the 2050 net zero emissions as an important indicator to alleviate the climate crisis, legislate and set more active carbon neutral goals. From countries, cities, and corporate institutions, one after another have proposed carbon reduction practices to show that countries have a strong consensus on carbon reduction. Internationally, two major carbon reduction practices, namely "renewable energy development" and the "circular economy," have been proposed from the energy structure and production aspects. Taiwan is an export-oriented country with a strong reputation in manufacturing. It is bound to respond actively to countries and major brands around the world for net-zero carbon emissions, such as carbon border tariffs, supplier guidelines, etc.

The MCL/ITRI has long been concerned about international technology trends, and is committed to material technology research and development. MCL/ITRI also regards the circular economy as an important means of net-zero sustainable development, and has deployed a number of recycled materials and process technologies in the panel industry, bio-plastics, solar photovoltaic and other industries, and worked with the industries to create new opportunities for net-zero sustainable recycling. The technical achievements are described as follows:

1. Waste LCD panel recycling system

Domestic LCD panel factories have about 3 million waste panels each year. The waste LCD panel recycling system developed by MCL can successfully separate and reuse liquid crystal, metallic indium and glass, and minimize the harm to the environment. It can process 3 metric tons of liquid crystal panels per day and 1,000 metric tons per year. The liquid crystal removed from the panel can also be reused in the LCD panel manufacturing process, helping manufacturers save US$15 million each year. In addition, the use of LCD glass made of nanoporous material to treat wastewater can reduce the cost of electroplating waste treatment from NTD120 per ton to NTD60. This technology is used to assist well-known foreign electronics factories to establish recycling systems. This technology won the 2017 R&D 100 awards (Figure 1)

Figure 1. Waste LCD panel recycling system

2. Carbon dioxide capture and reuse technology

There are more than 40 types of CO2 capture systems in the world, with an average energy consumption of about 3.5 GJ/ton-CO2. Our new chemical adsorption formula (sterically hindered amines) can control the energy consumption below 3 GJ/ton-CO2 with a cost of less than $32 USD/ton-CO2, and it has been verified by many domestic companies in different fields. Developing environmentally-friendly application materials of methanol/NIPU/PU/polyol through CO2 conversion technology can connect with related products to assist the industry reducing direct carbon emissions and opening up new business opportunities (Figure 2).

Figure 2. Field testing area for CO2 capture and reuse technology in the Taiwan Power Company

3. Bio-polyester material

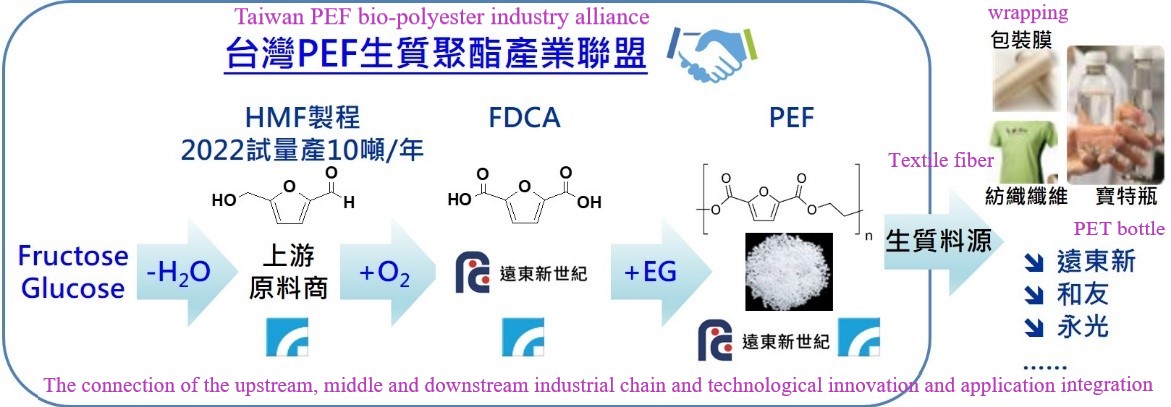

PEF polyester material is a biomass source, is recyclable and has high gas barrier properties. International manufacturers are quite optimistic about the potential of the PEF application market in the future, and have invested in material development and accelerated the pace of industrialization. The institute has a complete patent layout for the production of HMF, FDCA monomer catalysis, purification process technology and high molecular weight PEF polymerization catalyst from sugar raw materials. At present, it has connected domestic manufacturers (including CNPC, Far East New, etc.) to establish the Taiwan PEF bio-polyester industry alliance. Through the connection of the upstream, middle and downstream industrial chain and technological innovation and application integration, Taiwan can achieve an important position in the global green bio-materials (Figure 3).

Figure 3. Taiwan PEF bio-polyester industry alliance

4. Easy to disassemble and recycle solar modules

The development of renewable energy drives the global construction of solar photovoltaic systems. As the service life of the modules expires, the problem of discarded modules continues to expand. Therefore, the MCL/ITRI broke through the traditional treatment-burial model and introduced redesign, easy-to-disassemble solar modules, developed composite thermoplastic packaging materials, and initiated easy disassemble and recycling procedures to develop a complete green manufacturing process. Under the premise of maintaining the same commercial regulations for the modules, the simultaneous simplification of the module structure has effectively reduced the difficult-to-recycle waste of module materials by about 3%. Combining the development of the full-cycle PV module recycling value chain, the creation of recycling value is expected to increase from the original NTD 400 million yuan/GW to NTD1.6 billion /GW (Figure 4).

Figure 4. Easy to disassemble and recycle solar modules

The innovation of material technology can change the value system of the ecological chain from the beginning. As the most important material chemical research and development institution in Taiwan, the MCL/ITRI will continue to lead the research and development team to invest in circular research and development and input new thoughts on the circular economy into the domestic industry in order to guide the global supply chain based in Taiwan, and create a new opportunity for net zero carbon emissions.

STAY CONNECTED. SUBSCRIBE TO OUR NEWSLETTER.

Add your information below to receive daily updates.