Deep Learning for Intelligent Transportation Systems in Long-term Care 2.0 Plan

Author(s)

Chien-Yao HuangBiography

Dr. Chien-Yao Huang received his Ph.D. degree in mechanical engineering from National Chiao Tung University. He is currently a research fellow at Taiwan Instrument Research Institute (TIRI) of NARLabs. His expertise includes optical and mechanical components R&D and intelligent manufacturing application. Dr. Huang has years of experience in ISO 9001, ISO 27001, ISO 17025, and IEC 62443 standard systems. He is currently responsible for the R&D and application of intelligent manufacturing and industrial control systems security.

Email: msyz@narlabs.org.twAcademy/University/Organization

National Applied Research LaboratoriesSource

https://www.youtube.com/watch?v=LcwhuoHABwU-

TAGS

-

Share this article

You are free to share this article under the Attribution 4.0 International license

- ENGINEERING & TECHNOLOGIES

- Text & Image

- August 18,2021

Taiwan Instrument Research Institute (TIRI) of National Applied Research Laboratories (NARLabs) is a provider of the customized advanced instrument research and development platform required for innovative domestic research. Over the years, it has been committed to helping industry, academia, and research circles develop various advanced instruments and equipment. TIRI's outstanding contributions can be found in areas from the optical payload of space remote-sensing satellites to the deep-sea hyperspectral system. In recent years, in addition to its development of intelligent manufacturing technology, TIRI has been, by providing its facilities, assisting academic and research circles in verifying developed sensors and related intelligent manufacturing technology. By so doing, TIRI has helped to accelerate the application of technology in the field. This article summarizes the application results of intelligent manufacturing technology developed by TIRI and the academic research teams participating in the platform in recent years. It is expected that more academic and research teams will realize their innovations through the assistance of TIRI in the future.

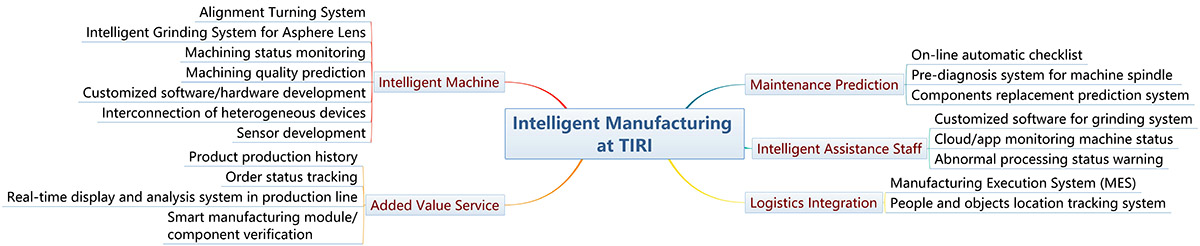

For a long time, Taiwan Instrument Research Institute (TIRI) of National Applied Research Laboratories (NARLabs) has acted as a provider of customized advanced instrument R&D platforms required for innovative research. It has assisted in translating academic research results into products, and has implemented intelligent machinery-related projects for the Ministry of Science and Technology (including sensors, intelligent machinery networking, and advanced manufacturing information security projects) since 2015. Furthermore, taking its optical factory as an example, TIRI is committed to developing intelligent manufacturing technology and applications for the production line (Fig. 1), thereby leading the evolution of Taiwan's machinery industry to digital manufacturing.

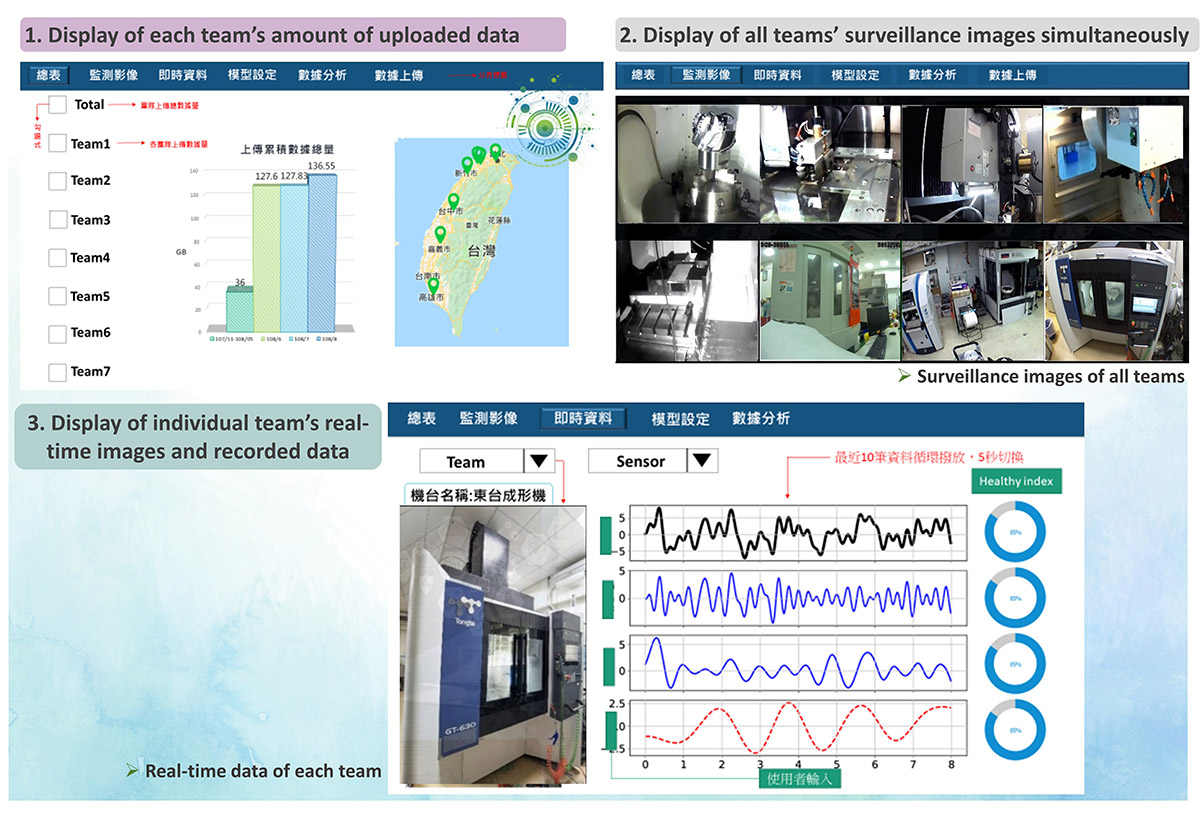

The intelligent machinery networking project is conducted by a research consortium which integrates research teams from National Taiwan University, National Central University, National Chung Cheng University, Cheng Shiu University, National Taiwan University of Science and Technology, and National Chung Hsing University. Real-time machine information can be displayed in the intelligent machinery networking situation center (Fig. 2). Data sharing between these teams can help them optimize the technical strength of data applications, allowing them to make breakthroughs in intelligent manufacturing technology. Take several research outcomes for example. The prediction accuracy (r-score) of turntable thermal displacement of the turning centering system developed by TIRI can reach 0.997. The team from National Chung Cheng University used sensor fusion to capture 28 signals simultaneously and increased the signal-to-noise ratio to more than 5 dB. A precision mold process optimization system was established by the team from National Taiwan University to shorten the same process time by 12% and reduce the surface roughness to 10%. The team from National Central University developed intelligent electric discharge machine network optimization estimation technology and predicted the accuracy of the surface roughness after machining to be 91.58%, realizing the virtual measurement target.

Fig. 1 Application examples of TIRI’s intelligent manufacturing technology

Fig. 2 Intelligence machinery networking situation center

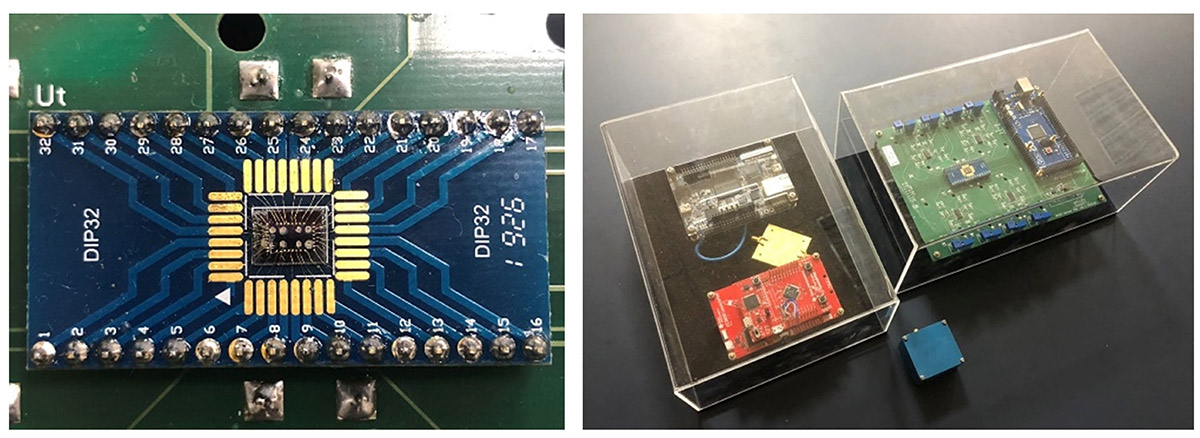

The sensor service platform provides sensor component back-end system circuits and modular design services to shorten the process from technology integration to industrialization, improves independent R&D capability, and increases the international competitive advantage of sensors. Fig. 3 shows the sensor module developed by the team led by Professor Ting-Jen Hsueh from National Kaohsiung University of Science and Technology. By using this platform (with analog/digital conversion circuit, calculation, and communication function), it is possible to use wireless communication for data transmission, and it is suitable for applications in intelligent machinery (complete machine/key components), electric hand tools, and gas sensing modules for mobile devices.

Fig. 3 Sensor network system integration test platform

(In collaboration with Professor Ting-Jen Hsueh’s team from National Kaohsiung University of Science and Technology)

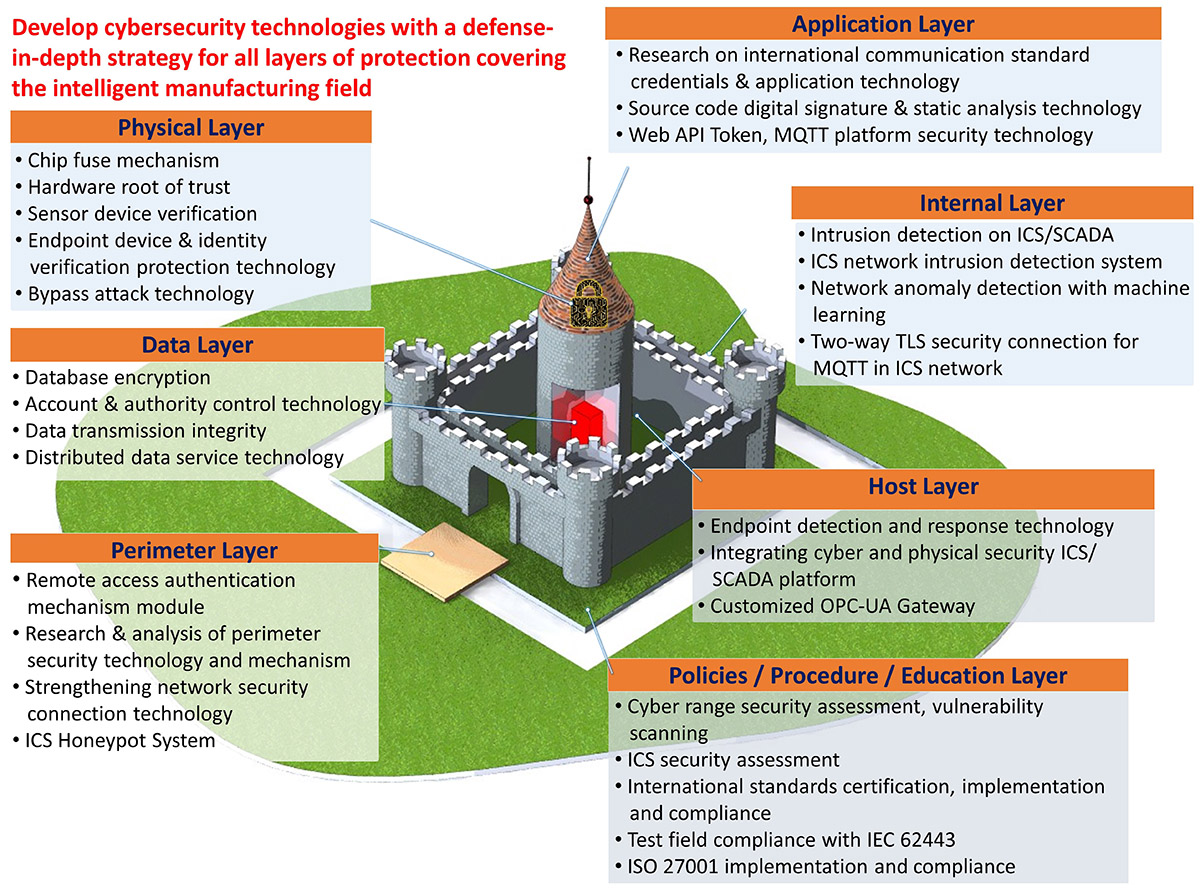

In addition to developing intelligent manufacturing technology, information security is critical. TIRI has passed ISO 27001 certification, and plans to build an intelligent manufacturing information security test field this year to take stock of issues related to industrial control information security (Fig. 4). Moreover, TIRI will develop cybersecurity technologies with a defense-in-depth strategy, so it is expected to become the first domestic field to be qualified for IEC 62443 industrial control information security certification in 2022. Furthermore, eight university teams (including 36 professors and 84 students) have participated in this project to test its robustness. With a total of 108 pieces of intelligent manufacturing equipment, the field information security status is known through on-site offensive and defensive drills. Additionally, TIRI is cooperating with TÜV Rheinland to jointly cultivate 100 technical personnel for industrial control information security, which is expected to alleviate the high-level talent gap in industrial control information security due to the development of intelligent manufacturing technology.

Fig. 4 Industrial control information security technical inventory

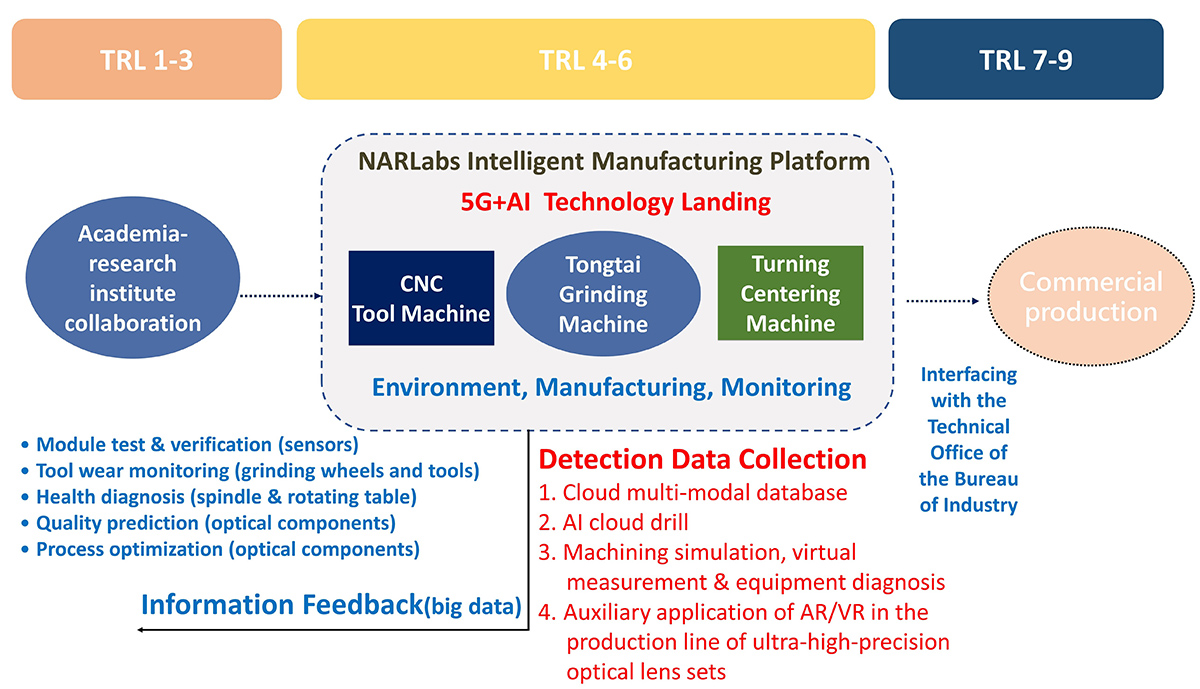

TIRI will enhance intelligent manufacturing-related facilities and technology in the future, including various types of machining and testing equipment and technology. It plans to introduce 5G private network signals through environmental control and MES process management to serve as an intelligent manufacturing technology verification and collaboration platform. In addition, it will help academia and research institutes carry out long-term technical verification of AI algorithms and self-made sensors (Fig. 5). TIRI can effectively promote the commercialization of academia’s innovation, narrow the gap between academia’s ideas and market needs, and accelerate technology application.

Fig. 5 The development and verification platform for academia and research institutes

STAY CONNECTED. SUBSCRIBE TO OUR NEWSLETTER.

Add your information below to receive daily updates.