Robust Raman Tags for Enhancing Imaging Contrast of Brain Tumor Cells

Author(s)

Charlie ChenBiography

Charlie Chen has been general manager at Bosch Rexroth Taiwan since July 2020. In this role, he oversees business activities of the company, promoting drive and control technologies for industrial applications in Taiwan.

Academy/University/Organization

Bosch Rexroth TaiwanSource

https://apps.boschrexroth.com/microsites/ctrlx-automation/en/

https://www.bosch-presse.de/pressportal/de/en/the-german-innovation-awardbr-goes-to-bosch-rexrothbr-ctrlx-automation-as-the-brain-of-the-modern-factory-230868.html

https://www.bosch-presse.de/pressportal/de/en/bosch-puts-first-5g-campus-network-into-operation-221632.html-

TAGS

-

Share this article

You are free to share this article under the Attribution 4.0 International license

- ENGINEERING & TECHNOLOGIES

- Text & Image

- August 17,2021

Open platforms for smart machinery have been in the spotlight recently. In the wake of the transition towards smart machinery, machine manufacturers that traditionally supply hardware play a crucial role. With open platforms, developers can tailor applications to their needs without being bounded by the conventional architecture of controllers. In case of any process or function enhancement, with open platforms, machine manufacturers can remotely install or update functions after the machines are exported, making automation as easy as handling a smartphone. In this vein, open platforms support machine manufacturers to go beyond the role of hardware providers by making the application of smart machines even more flexible and software functions much more advanced, surpassing the hardware limitations. This brings together the previously distant worlds of hardware and software and, in turn, incubates new business models.

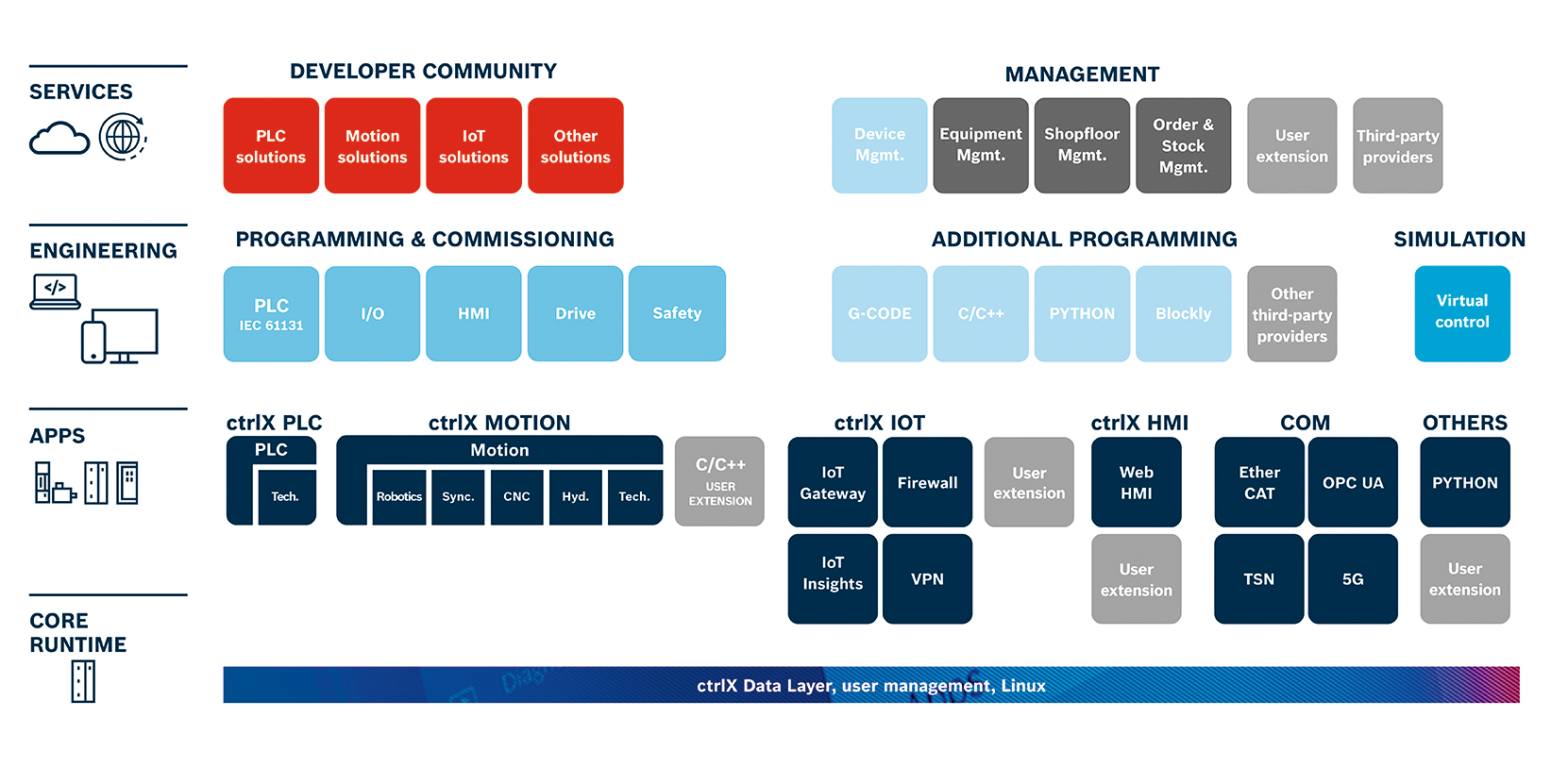

Figure 1. ctrlX AUTOMATION enables hardware and software integration with its solid structure

In the wake of digitalization, users are increasingly thinking digitally. Habits established through apps from the smartphone world are transferred to automation needs. Like smart phone users, smart machine users would be eager to try out new functions easily and quickly in small-scale projects on the machines. However, what every mobile phone user can do in seconds, however, often means weeks of work for machine manufacturers. While the latest functions can be added to smartphones simply by using an app, this usually requires a great deal of effort in the case of production machinery. This is why open platforms are making machines smarter. With open platforms, developers can tailor applications to their needs without being bounded by the conventional architecture of controllers. In case of any process or function enhancement, with open platforms, machine manufacturers can remotely install or update functions after the machines are exported, making automation as easy as handling a smartphone.

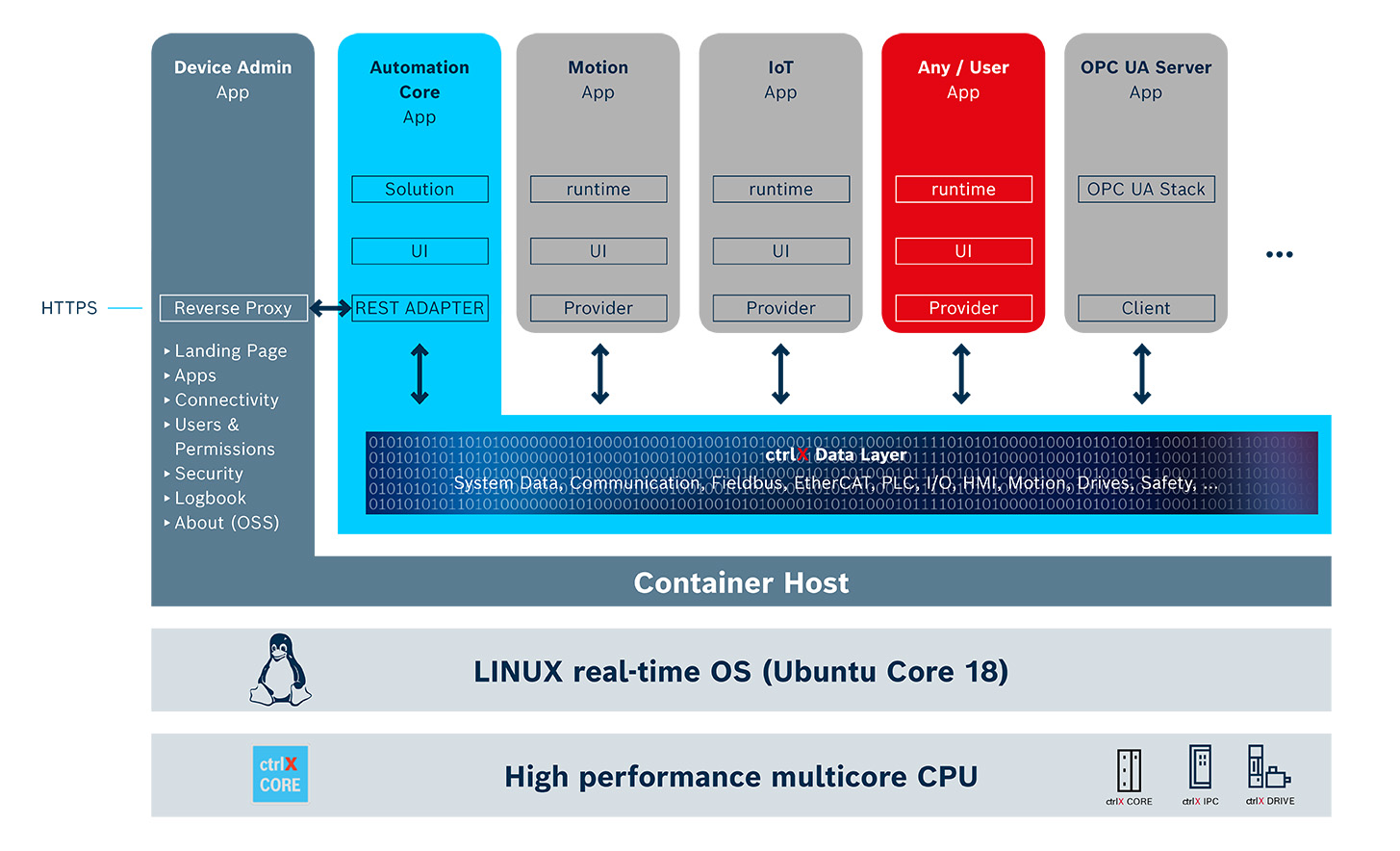

Bosch Rexroth, part of the Industrial Technology business sector of the Bosch Group, is a pioneer of open platforms for smart machinery. Bosch Rexroth’s ctrlX AUTOMATION system is the first open, 5G-enabled control platform in the market (Figure 1). Within the platform, users can utilize applications from Bosch Rexroth and third-party providers, or produce applications themselves and share them with other companies in the ecosystem. The core of this open platform builds on the ctrlX Data Layer. With the ctrlX Data Layer, developers can customize applications for machines in the Linux environment. It also allows data exchange between applications and corresponding machines (Figure 2). For instance, after an advanced Internet of Things (IoT) application is created with Node-Red on this platform by developers, machine manufacturers can directly purchase the function via the ctrlX App Store to upgrade the remote monitoring capability of the machines.

Figure 2. Data Layer is the core of ctrlX AUTOMATION

On top of that, the ctrlX World open ecosystem is growing, accommodating more than 20 partners as of June 2021 (Figure 3). The open ecosystem is a bridge that integrates hardware and software. In this world, you could find any hardware and software resource that smart machines need, like web-based human-machine interface (HMI), IoT, information technology systems for factories, intelligent components, software service, vision systems, sensors, etc. This is a vital advantage of the ctrlX AUTOMATION as the ecosystem gathers the domain knowledge of Bosch Rexroth, third-party providers, and customers to co-create automation solutions.

Figure 3. The ctrlX World ecosystem

Smart machinery enables the future of the automation industry, whereas open platforms are the brains of the modern factories that make machines more intelligent. In the future, machines should support conventional programmable logic controllers (PLC) and PC-based ones for programming languages like Python, JavaScript, and C/C++ to fulfill more advanced requirements to develop smart machinery. The concept can be further extended to smart production lines or ultimately smart plants with the ctrlX Device Portal cloud service. Open platforms are not only the pillar of smart machinery but also the foundation for smart factories.

STAY CONNECTED. SUBSCRIBE TO OUR NEWSLETTER.

Add your information below to receive daily updates.