Recreating new life in the periodic table-high-entropy alloys

Author(s)

Fan-Tien ChengBiography

Professor Fan-Tien Cheng joined the Chung Shan Institute of Science and Technology (CSIST) in 1976, serving as Research Assistant at the most basic level and then was promoted to Senior Scientist, a position he held for 19 years. Professor Cheng’s research achievements are significant both academically and industrially in the domains of production manufacturing improvement, production automation, and e-manufacturing. Among those, he has been taking the lead especially in the academic and practical applications of VM technologies. So far, he has more than 30 VM-related journal papers, dozens of VM invention patents both domestically and internationally. The AVM and AMCoT systems he developed with his team helped FECMCO/FATEK win the Excellent CNC Lathe Award in TIMTOS 2017; his “smart machinery cloud service platform” has been successfully presented to President Ing-Wen Tsai and Minister Jung-Chin Shen, the head of the Ministry of Economic Affairs. He is currently in his second-term as President of the Chinese Institute of Automation Engineers (CIAE) since 2017.

Academy/University/Organization

National Cheng Kung University-

TAGS

-

Share this article

You are free to share this article under the Attribution 4.0 International license

- ENGINEERING & TECHNOLOGIES

- Text & Image; Video

- December 20,2019

The current Industry 4.0 related technologies emphasize productivity improvement but not quality enhancement; in other words, they can only keep the faith of achieving nearly Zero Defects (ZD) state without realizing this goal. The key reason for this inability is the lack of an affordable online and real-time TOTAL-INSPECTION technology. By adopting the developed Automatic Virtual Metrology (AVM), ZD can be achieved as AVM can provide the TOTAL INSPECTION data of all products online and in real time. Further, the developed Intelligent Yield Management (IYM) can be utilized to identify the root causes of the defects for continuous improvement of those defective products; as such, nearly ZD of all products can be achieved.

The novel Intelligent Factory Automation (iFA) System Platform was developed by integrating technologies such as Cyber-Physical Agent (CPA), Advanced Manufacturing Cloud of Things (AMCoT), Automatic Virtual Metrology (AVM), Intelligent Predictive Maintenance (IPM), and Intelligent Yield Management (IYM), etc., so as to provide a total-solution package for implementing Intelligent Manufacturing. The iFA System serves as a game changer for both high-tech (e.g., semiconductor, flat panel display, solar cell, etc.) and traditional (e.g., machine tool, aerospace, carbon fiber, etc.) industries to upgrade Industry 4.0 to Industry 4.1 in pursuit of increasing productivity as well as realizing the goal of ZD of all products.

There are two options of the iFA System Platform for the customers to choose from: the “Server-based version” and the “Cloud-based version” are provided according to different customer requirements. The content of the two versions is illustrated in the following sections.

1. The Server-based iFA System Platform

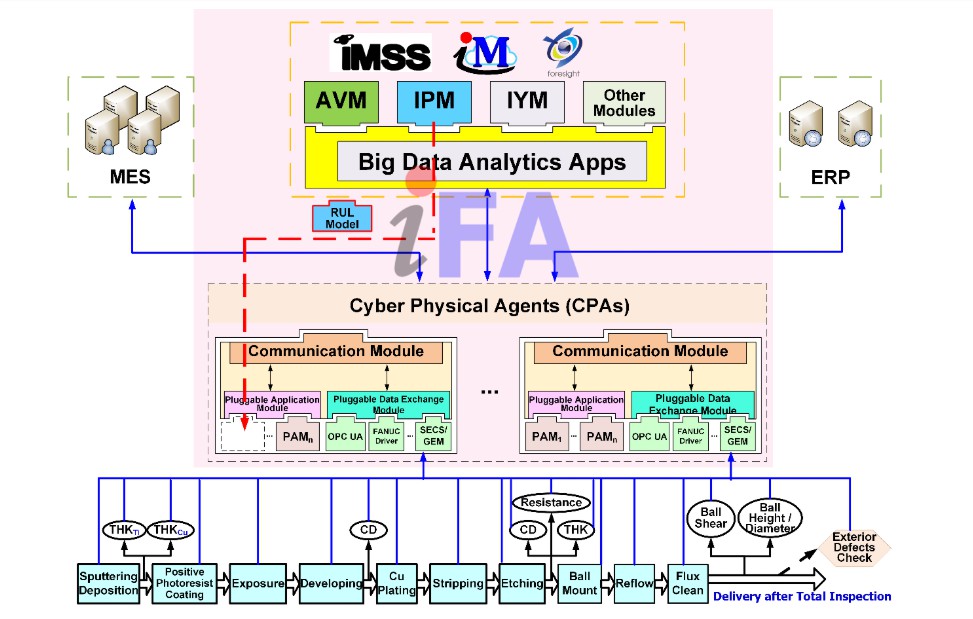

For companies with strong capital or low demand of the cloud, a buyout Server-based version of the iFA Platform as shown in Figure 1 is recommended. The Internet of Things (IoT) technology is utilized to develop a CPA at the machine side. CPA is equipped with various Equipment Drivers for different industries, such as SECS/GEM and Interface A for the semiconductor industry, OPC-UA and MT-Connect for the machine-tool industry, etc. The Communication Module in CPA is for connecting the Internet and the cloud. Various intelligent services can be implemented as Pluggable Application Modules (PAMs) and plugged into CPA for edge computing. Then, a Big Data Analytics Applications (BDAA) platform is constructed to include various intelligent manufacturing functions such as AVM, IPM, IYM, Tool Life Management (TLM), Equipment Management System (EMS), etc. AVM can convert offline sampling inspection with metrology delay into online and real-time TOTAL INSPECTION of all the workpieces; IPM can monitor the health status of a key device and predict its remaining useful life (RUL); IYM is used to quickly identify the root causes that affect the yield; TLM is for online monitoring of cutting-tool status and providing proper tool-change time; and EMS monitors machine utilization and Overall Equipment Effectiveness (OEE).

Fig. 1. Server-based iFA System Platform

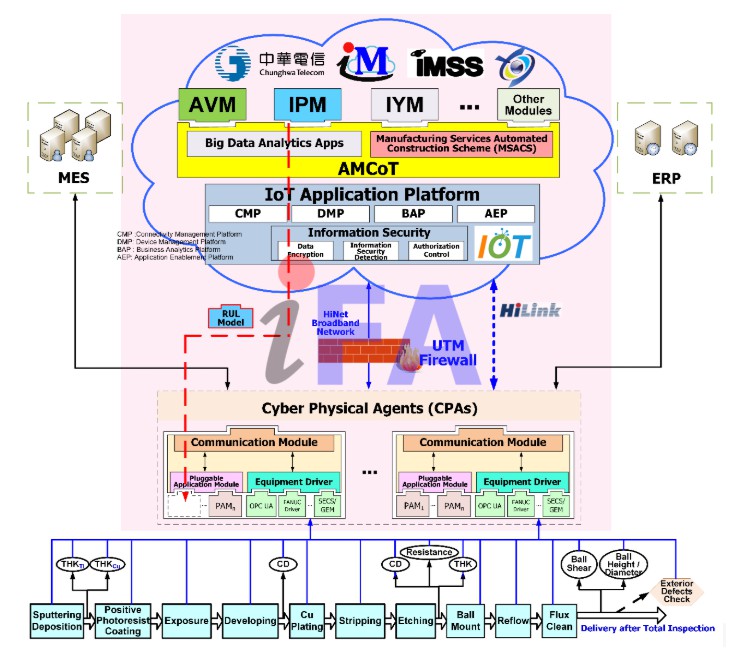

Fig. 2. Cloud-based iFA System Platform.

- Accomplishing Big-Data-Collection Infrastructure

[w/ CPA – Internet of Things and Edge Computing] - Accomplishing Cloud-Computing Infrastructure

[w/ AMCoT – Cloud Manufacturing] - Establishing Internet security and monitoring system

[w/ IoT Security Operation System – Information Security] - Accomplishing Workpieces Total Quality Inspection

[w/ AVM – Total Quality Inspection for Achieving Zero Defects] - Improving Production-Tools’ Availability

[w/ IPM – RUL Prediction Preventing Unscheduled Down] - Constructing Root-Causes Searching Infrastructure of Yield Loss

[w/ IYM – Root-Causes Identification of Yield Loss for Continuous Improvement] - Real-time monitoring of the Cutting-Tool status and providing adequate timing for tool replacement

[w/TLM – RUL Prediction of the Cutting-Tool status ] - Managing the Utilization of the factory and monitoring the Overall Equipment Effectiveness (OEE)

[w/ EMS – Equipment Management System]

STAY CONNECTED. SUBSCRIBE TO OUR NEWSLETTER.

Add your information below to receive daily updates.